In fact, the idea of designing a chemical-free packaging treatment system is much older. Twenty years ago, Guy Dumargue, who had just taken up his position as Chairman of the Executive Board, already wanted to eliminate the chemical treatment of packaging in aseptic filling machines. The idea was to integrate a high-energy electron beam bottle treatment upstream of the filling process, a technology that has already been successfully used for other applications. This was one of the first Delphine’s missions was given when she arrived at Serac in February 2000. But, after several years of testing and laboratory trials, the idea of sterilizing the bottles with high-energy electron beam was abandoned because it proved difficult to industrialize.

Almost 10 years later, the project took off thanks to a sustained collaboration with AEB, a start-up created by researchers from the Massachusetts Institute of Technology (MIT). They had developed a system for treating bottles with a low-energy electron beam. The Start-up was looking for partners to build the first aseptic packaging machine equipped with this treatment system. The partnership between Serac and this start-up is working quite well. The idea of creating a Joint Venture is gradually emerging in the minds of executives. But almost two years later, the start-up went bankrupt.

The decision was taken quickly to buy back the licenses and test benches and to continue the developments with French partners. It was in that year, 2012, that Nicolas Geslot joined Serac to work full-time on the BluStream? project, the eBeam treatment technology. For nearly 7 years, Nicolas developed this treatment technology. He is assisted by Hélo?se Gourraud for the bacteriology part, and by Jean-Eudes Dippe for the 3D design part.

In June 2019, an operational eBeam treatment module for caps was finally finished in the Serac laboratory located in La Ferté-Bernard at the group’s headquarters (France). A module is ready to join a customer’s workshop in a few weeks to start the last step: the industrial validation phase. It is an eBeam treatment module for caps that will be tested at this customer’s on one of its beverage filling lines. This module is a decisive step in the success of Serac’s “Zero chemicals” objective.

The goal is fast approaching!

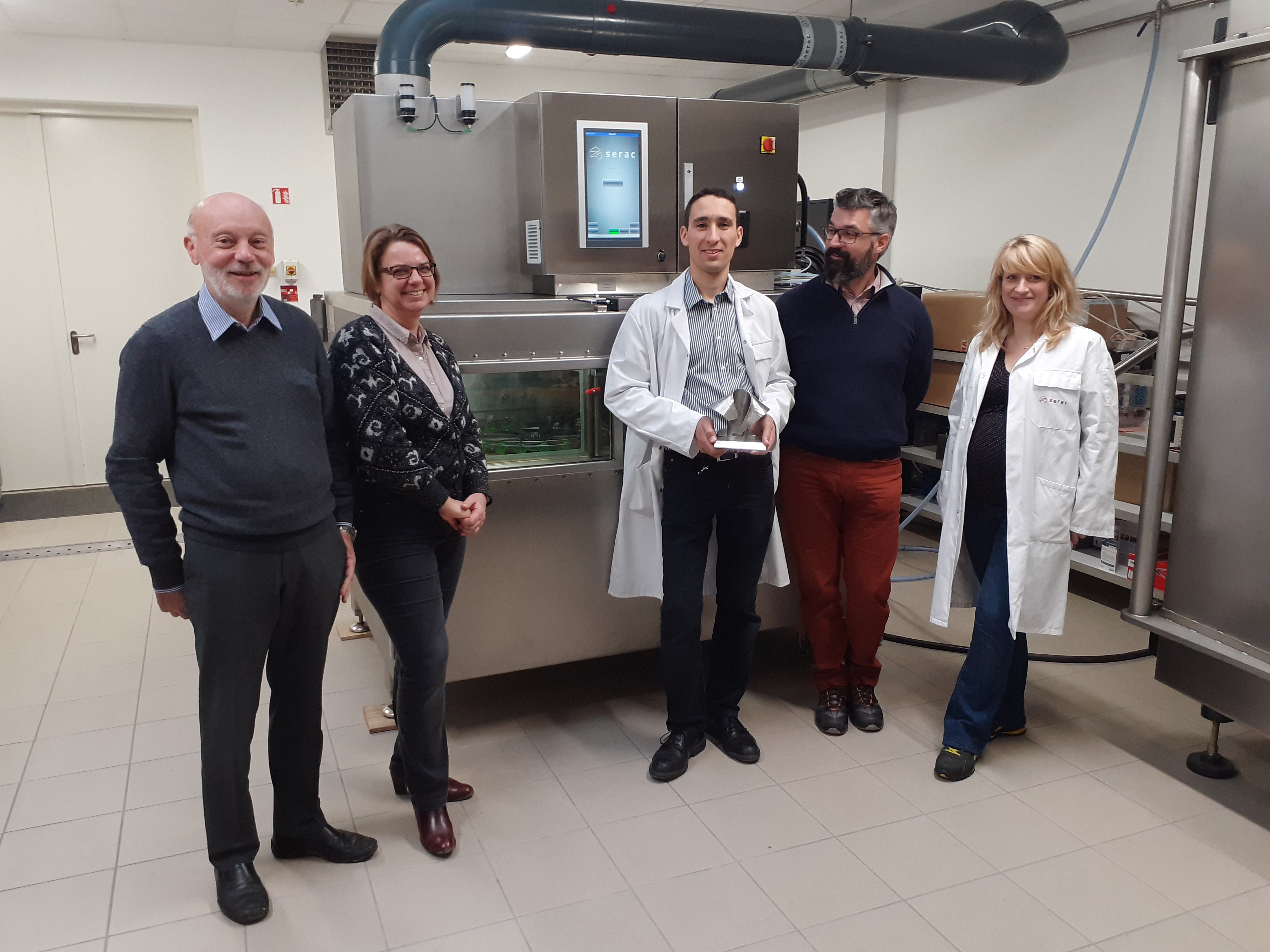

Jean-Marc Doré, President of Geppia & Delphine Gueguen, Technical Senior Manager for Sensitive Products at Serac

“ Our commitment to the environment at its fullest display. We are honored to receive this recognition from such a prestigious body. But all the kudos and congratulations go to our fantastic and dedicated Team that made all this happen. This is Imagination, paired with the desire to push the boundaries, at work.

True human teamwork indeed. Congrats guys, very well done. “

Guy Dumargue, Delphine Gueguen, Nicolas Geslot, Jean-Eudes Dippe, Hélo?se Gourraud

上一篇:Thierry Deau’s appointment as Chief Technical Officer of Serac group.

下一篇:The Modulo nozzle is now available for all Form-Fill-Seal (FFS) cup packaging lines